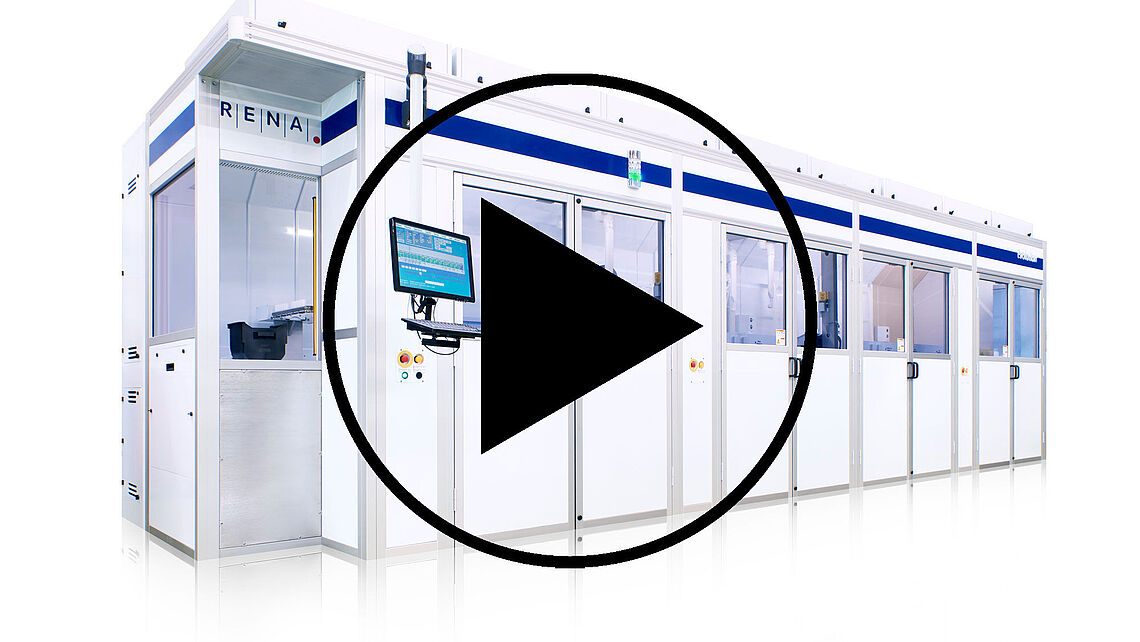

Evolution - fully automated, dry-to-dry semiconductor manufacturing wet bench

For high throughput wet processing of semiconductor wafers, RENA offers the “Evolution”, a fully automated linear wet bench. Multiple surface treatment processes such as cleaning, etching, resist striping and drying can be performed using the “Evolution”. This chemical station has flexible modular design with robust transfer robot and can be customized according to your specific process sequences. The “Evolution” enables the batch processing of simultaneous wafer lots as well as dry-to-dry processing.

High production yield, low cost of operation and outstanding process control are the main features of this platform. This superior process control is achieved through IDX Flexware software, one of the most advanced in the semiconductor industry with unique features and capabilities. Specialized process tanks such as TruEtch, FluidJet and SiEtch and Ultrasonic and Megasonic tanks as well as patented Genesis Marangoni dryer can be integrated in “Evolution” to meet the customers process specifications.

All RENA systems are compliant to SECS/GEM interface of factory host.