Equipment Upgrades

Customized solutions

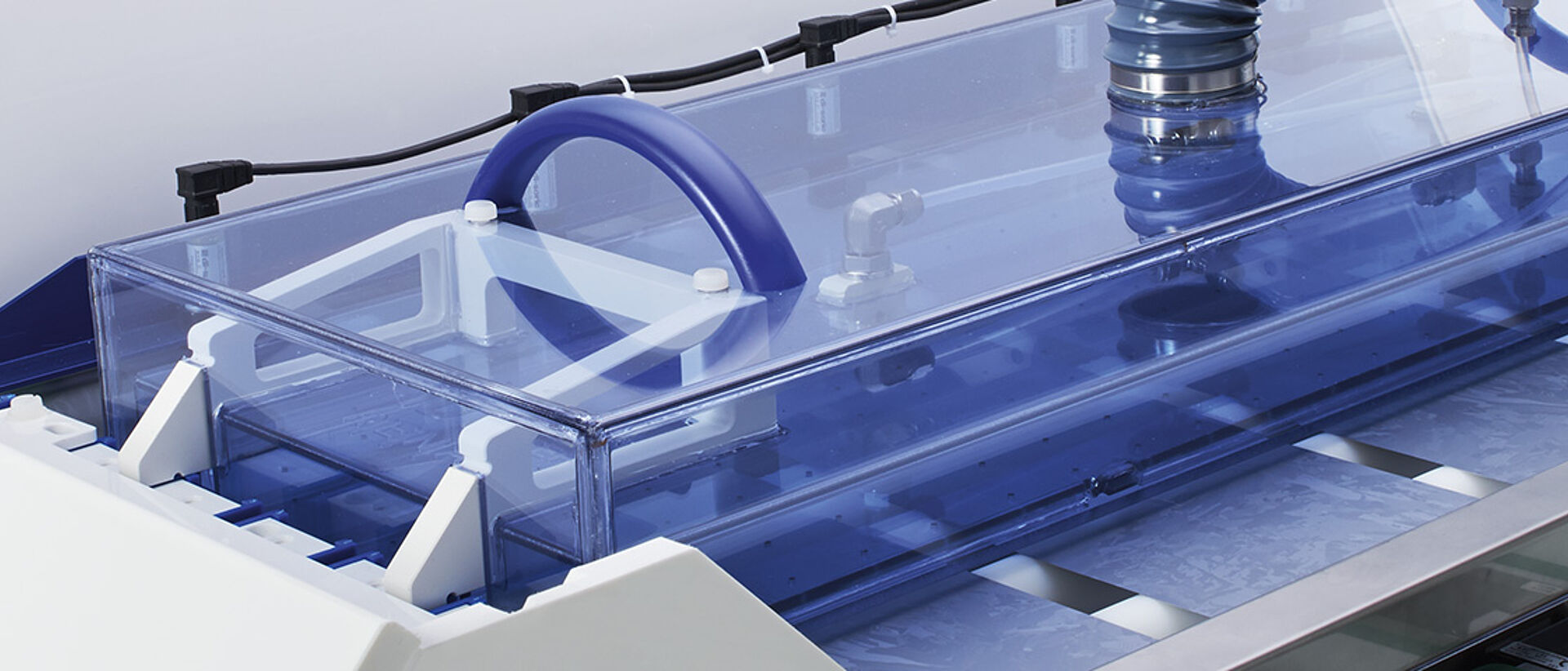

Flexibility is one of the key attributes for long-term success. So respond to changes in general conditions, such as increasing cost pressure or frequently changing technical requirements, by modifying your RENA machine. This will ensure that you continue to enjoy the high productivity from your machine and availability of parts to which you have become accustomed. Even over a longer machine service life. Our engineers develop solutions in close consultation with you. That way, we ensure that modification of your equipment is optimized to suit the new or changed requirements. We can take account of specific requirements, e.g.: upgrades in the cleanroom, without changing the machine’s dimensions, thus minimizing production disruption.

Upgrades are scheduled and integrated in accordance with standard GMP and EC guidelines. Our team of experts support you with consultancy and engineering services from your initial inquiry through to realization and integration.