High-End cleaning for High-End products

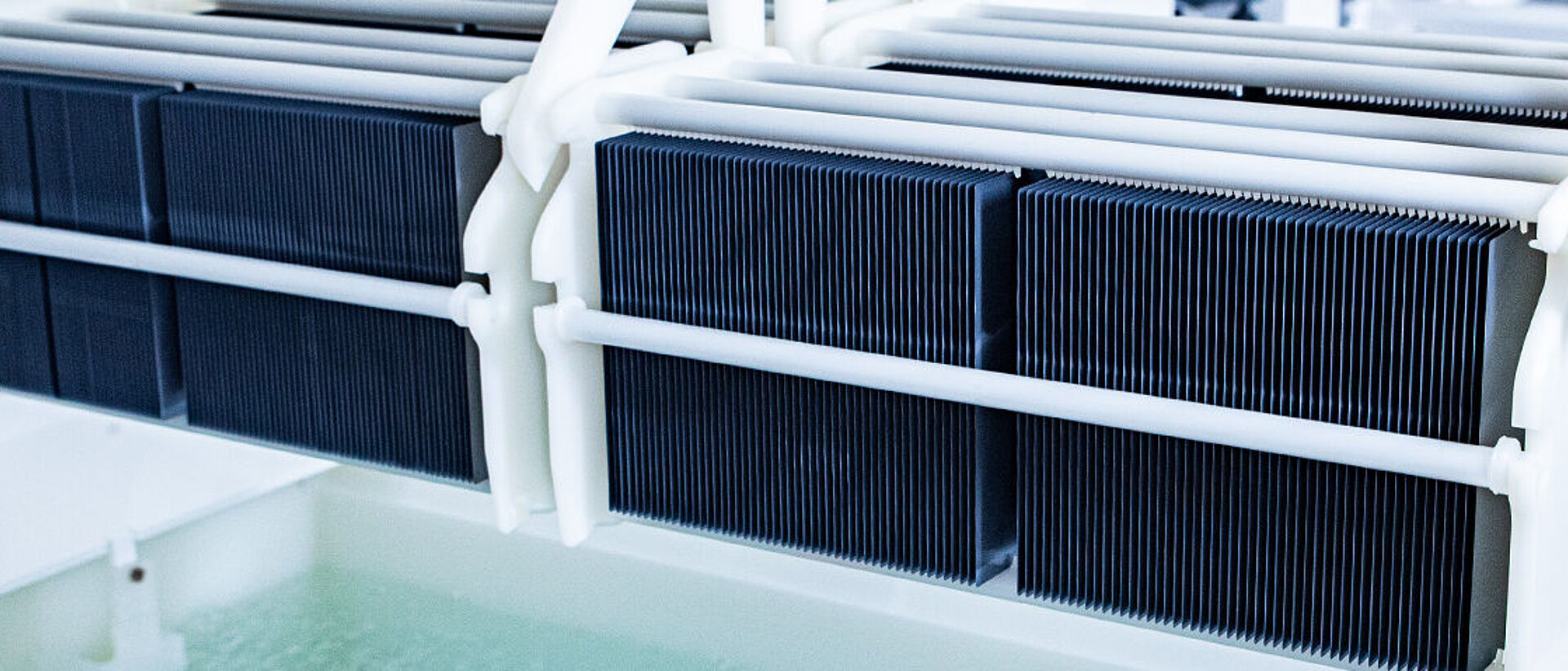

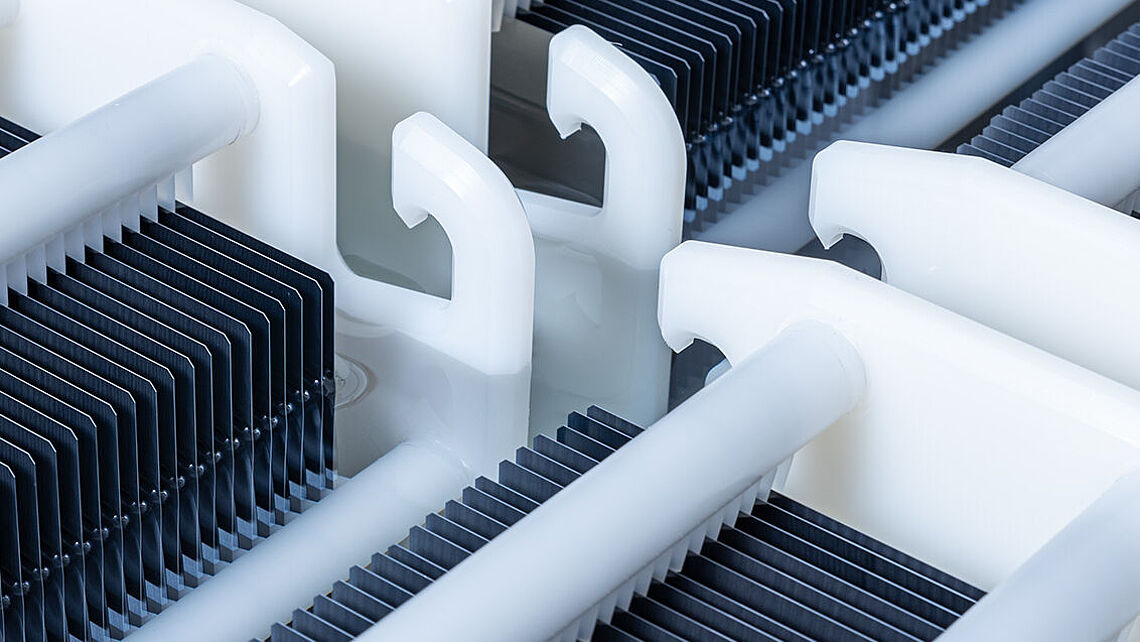

The RENA BatchClean N automated processing equipment is for batch-type cleaning processes for silicon solar cells. Depending on customer requirements, a large variety of alkaline and acidic processes are available. The equipment is based upon the RENA Batch N platform.