Medical Devices – New Technologies

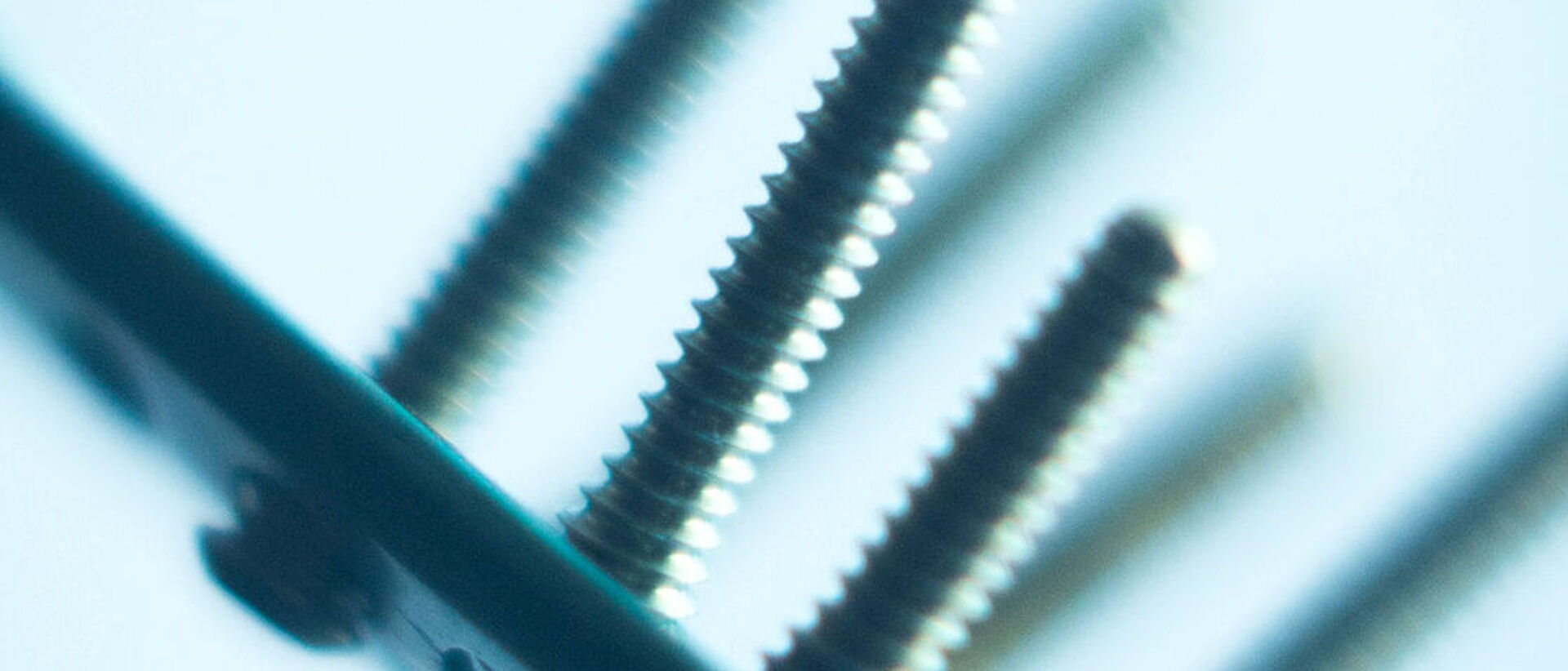

With our expertise in wet chemical surface treatment we support our customers to meet the demands of new and innovative technologies of the medical technology sector

Each surface treatment of medical devices requires a preceding and a subsequent cleaning. According to the surface treatment and cleaning requirements different sequences of cleaning process steps are necessary. The right combination of ultrasonic treatment, quick dump rinse, rinsing with chemicals and temperature adjustment reaches highest cleanliness, even for complicated structured and porous substrates. Different drying technologies complete the cleaning procedure.

The combination of a compact modular platform, automated process control and handling as well as the compliance of all regulatory medical technology requirements forms high quality production equipment for cleaning of a wide range of medical device cleaning, e.g. stents, surgical and dental instruments.