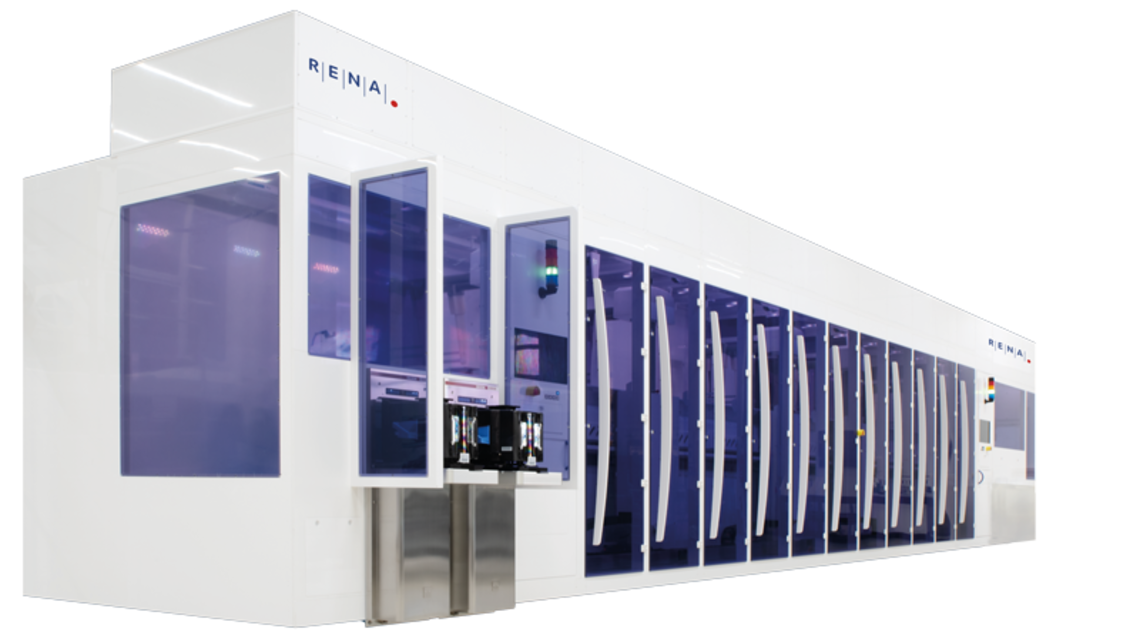

RENA Convergence - wafer processing platform - high throughput, precise process control

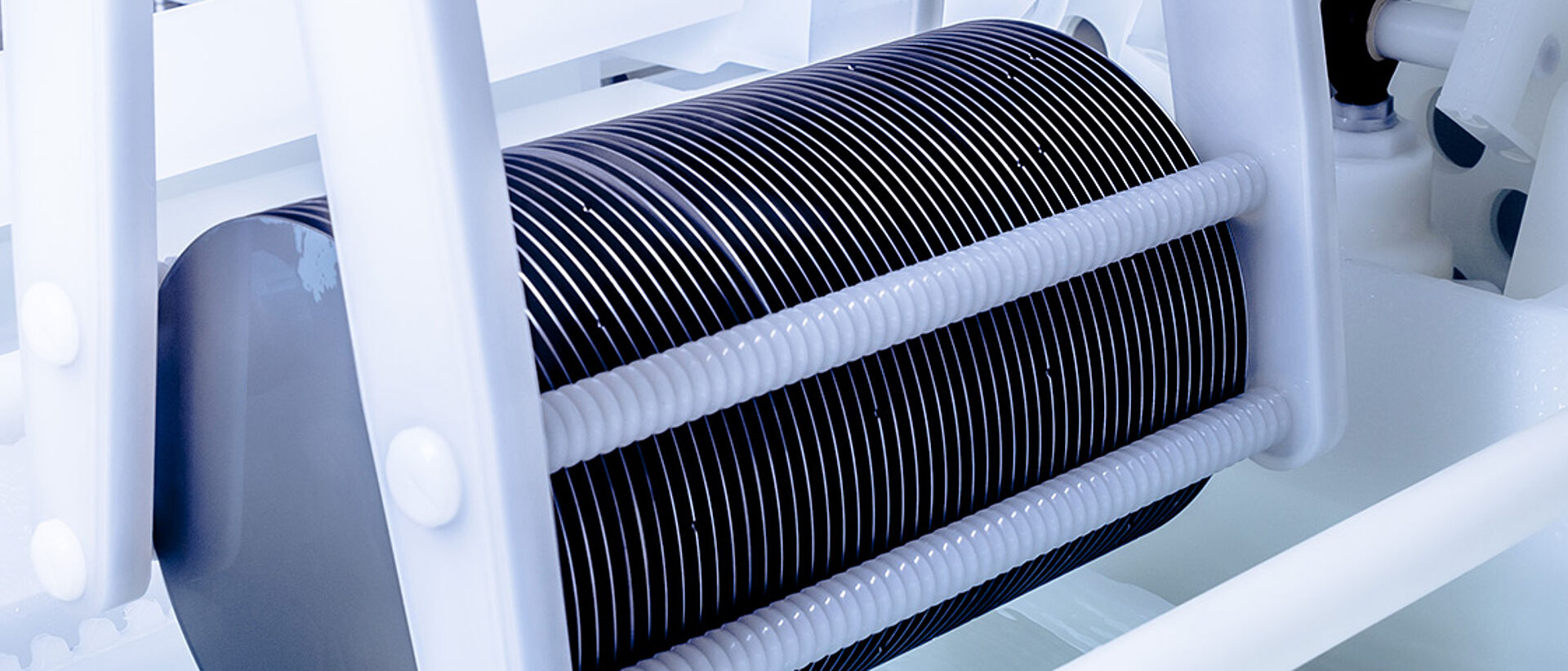

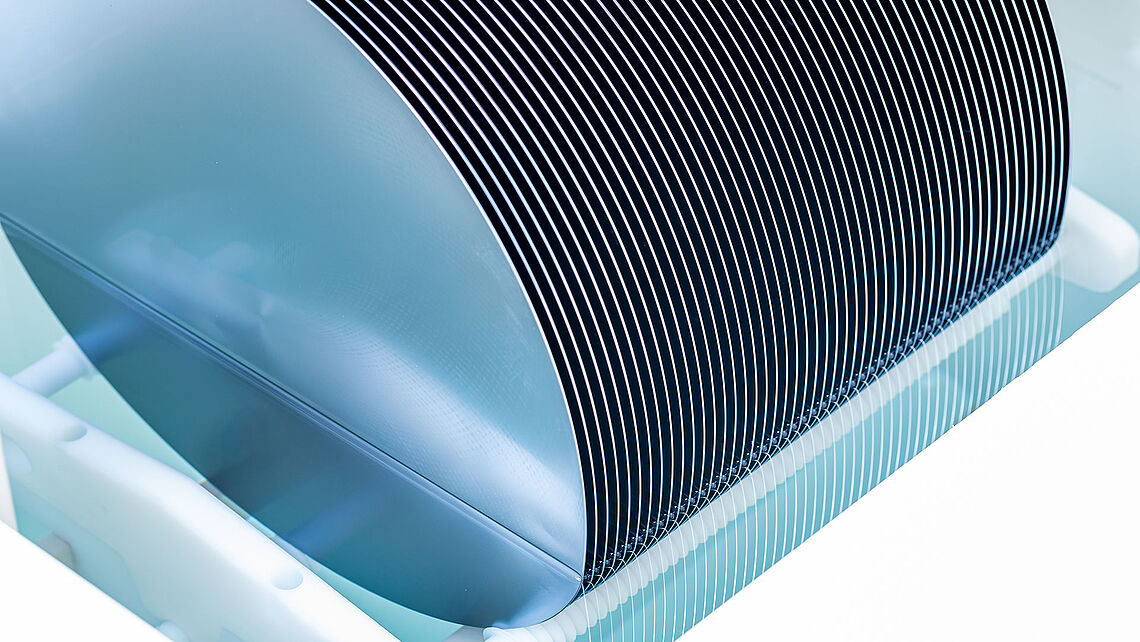

The RENA Convergence wafer processing platform, suitable for 6" to 8" and 12" wafers, combines advanced automation with excellent process control. A key feature of the highly flexible system is that it supports both carrierless and low-mass carrier processes for wafer sizes up to 12" (300 mm). Its modular design allows full customization to meet specific requirements. To offer maximum production quality control, the semiconductor wafer processing platform tracks all parameters during production. The RENA Convergence is engineered for high uptime, easy maintenance and highest throughput. Its flexible design features special tank options, parallel processing for multiple wafer thicknesses, and multiple dryer options.

- Etching

- Solvent

- Cleaning

- Rinsing

- Drying