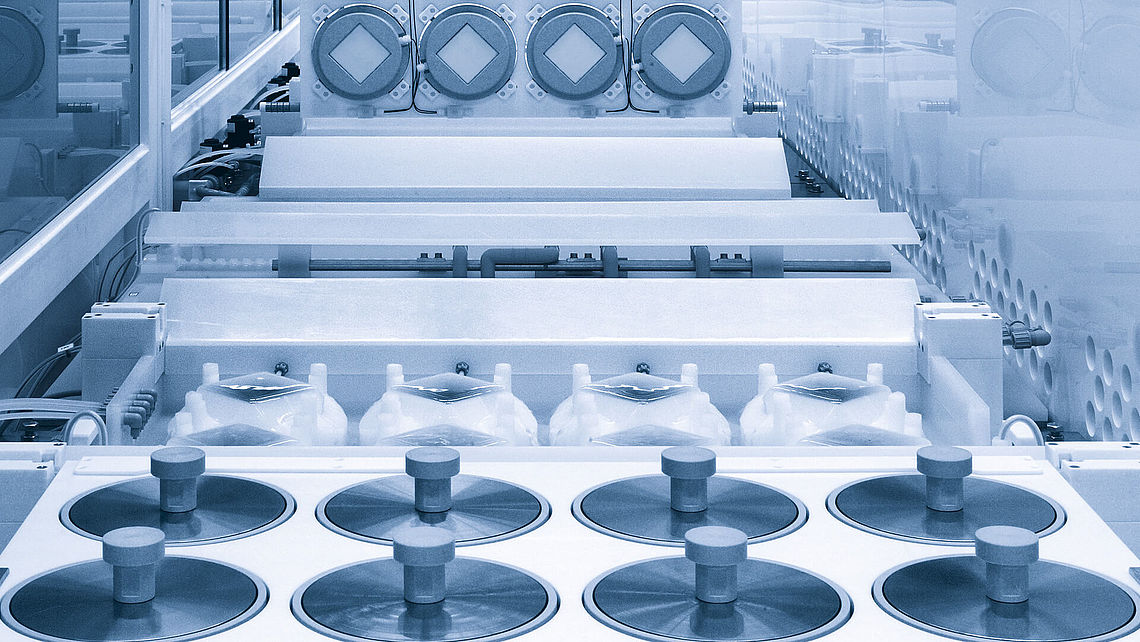

EPA – Automated electroplating

The RENA EPA system delivers accurate and flexible solutions for automated processes involved in electroplating. Its modular design enables customers to swiftly adjust the system in line with pre-defined or new process structures. It facilitates automated plating with pure metals and alloys (Au, Ag, Cu, Sn, Ni, SnAg) as well as various coating metals. Boasting an outstanding flow of fluid and tight control of the electrical field, the RENA EPA system delivers even plating at a high rate in automated processes.

Efficiency and precision

The highly scalable throughput and outstanding evenness of plating are just two of the major benefits of the RENA EPA system. Precision-perfect control options benefit a wide variety of semiconductor and microsystem technology applications, such as creating functional metal coatings for MEMS, micro-forming and moulding ultra-small parts for microsystems, producing optoelectronic components, or bumping.

The system offers customers a great deal of freedom when it comes to the size and geometry of the wafers, and options for expansion with extra process modules for treating, etching, and drying.