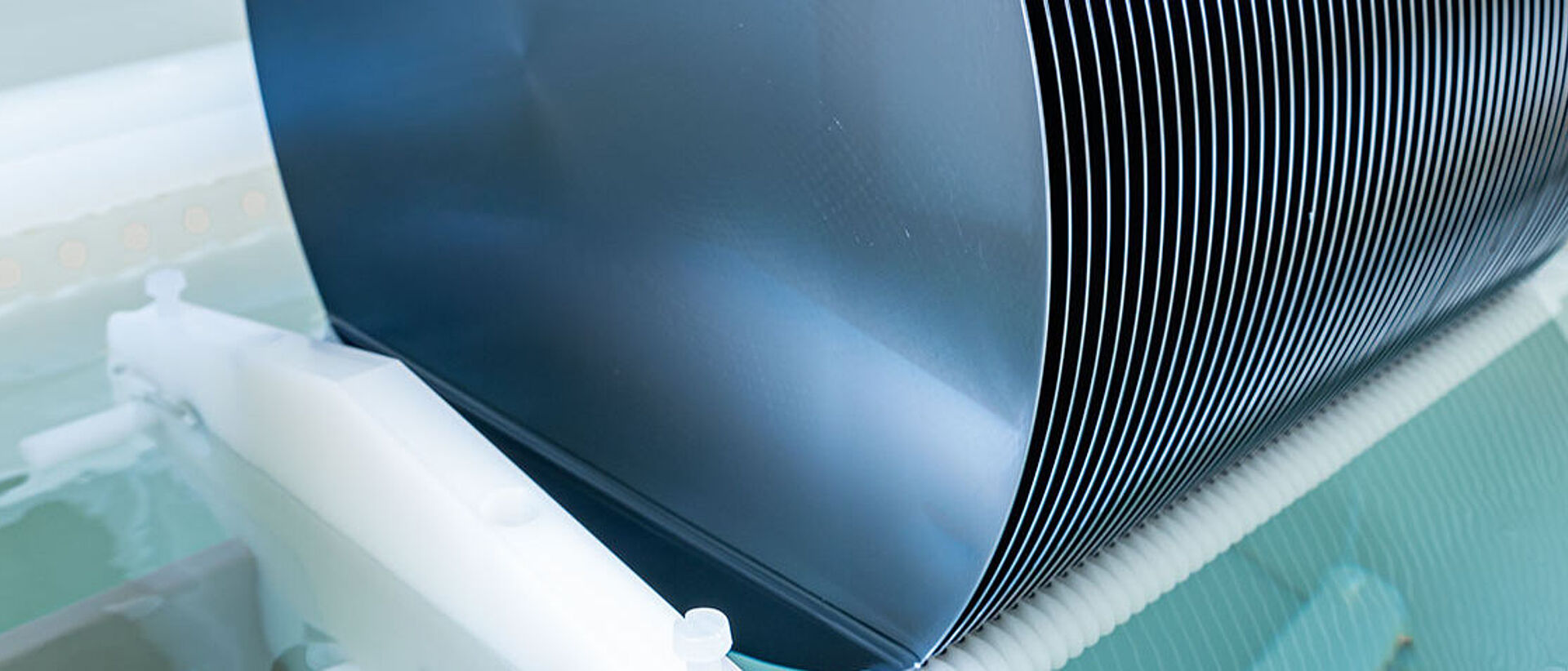

Integrated and standalone wafer dryers for semiconductor manufacturing

Wafer drying processes are essential for final quality of un-patterned wafers as well as fabricated devices. The main application of wafer dryers are removing of remaining watermarks and rinsing off any residues from previous process steps. For this purpose, The semiconductor segment of RENA offers a broad spectrum of integrated and standalone wafer drying stations. We supply customers with a family of spin rinse dryers (SRDs) so called COMPASS, patented Genesis Marangoni dryer and VaporDry. In both Genesis and VaporDry, isopropyl alcohol (IPA) is employed for residual and water removal. Our drying platforms are designed to be cost efficient while meeting customers particle performance specifications. All platforms are assisted by the IDX Flexware process control software which facilitates advanced process control and monitoring. Customers can handle various wafer sizes, up to 300 mm, using either high or low profile cassette. Our drying stations provide superior process results for various wafer materials such as silicon (Si), compound semiconductors, glass and sapphire.

RENA provides drying platforms that are suitable for reliable performance both at front-end-of-line (FEOL) and back-end-of-line (BEOL) applications. Genesis is suitable for the photo mask removal and nitride strip applications, since in one step process both rinsing and drying can be accomplished. In general, the manufacturing of integrated circuits (ICs), MEMS, high aspect ratio features, through-silicon-vias (TSVs) and complex surfaces can be supported by our drying platforms.