TOPCon Solar Cells

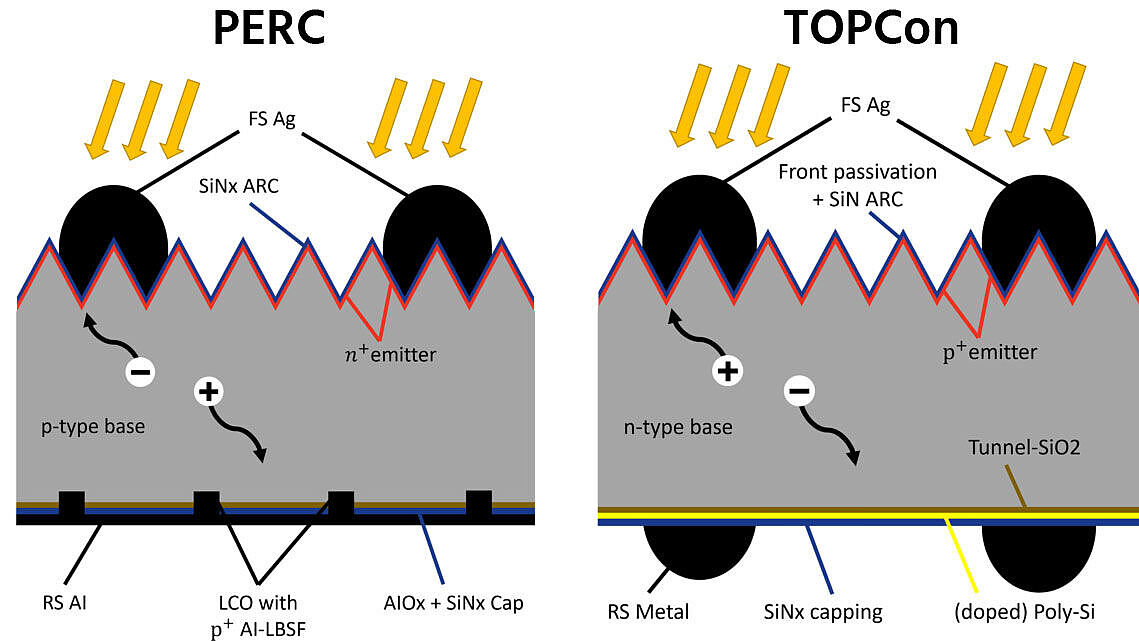

There are various ways to build a solar cell based on crystalline silicon. The main one used to be the “PERC” cell concept, a pragmatic compromise between efficiency and simplicity. However, efficiency was only achieved slowly after a lot of hard work.

One of the most promising candidates is the “TOPCon” cell concept, which improves efficiency levels in mass production.