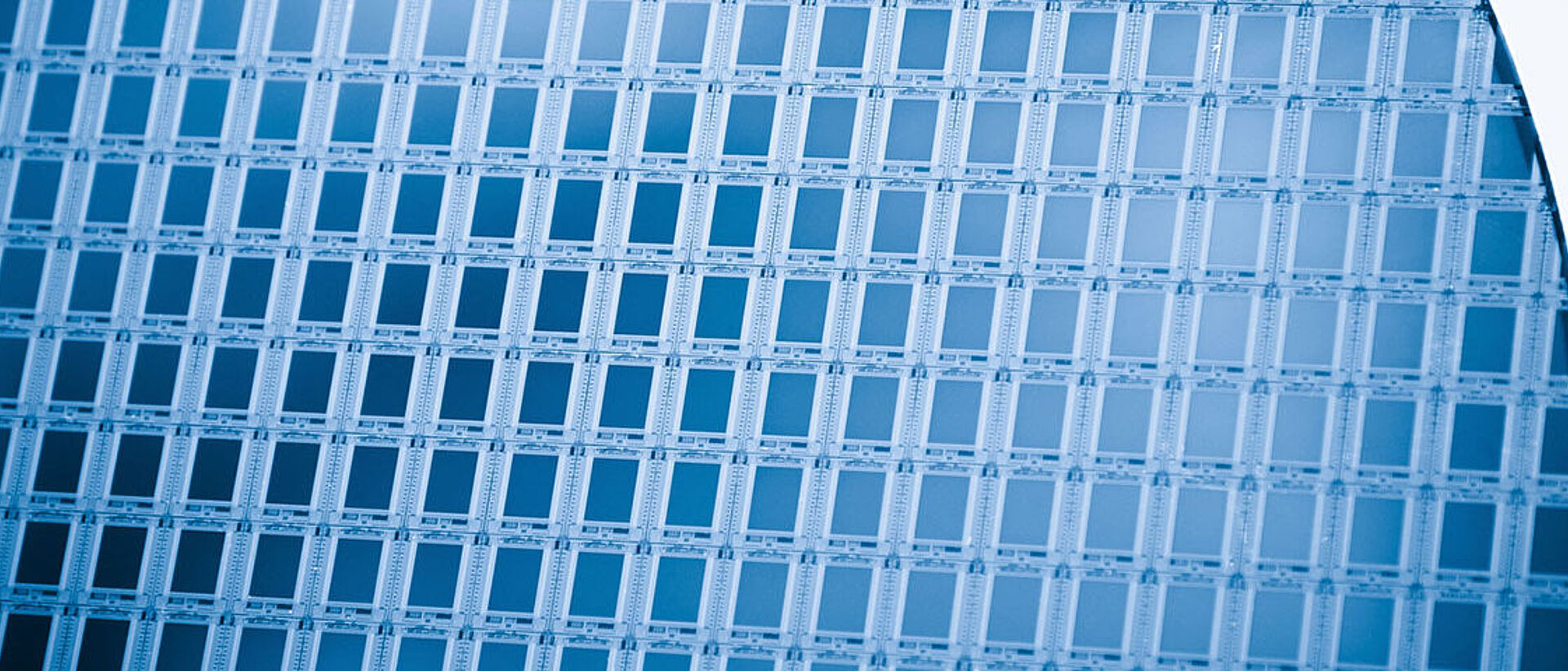

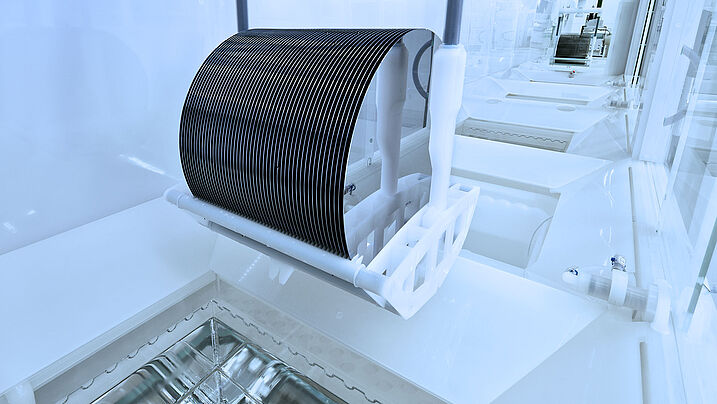

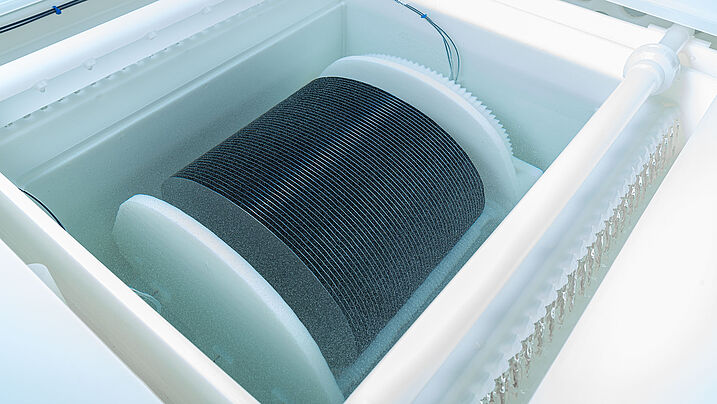

Delivering state-of-the-art semiconductor wet processing solutions, RENA provides wafer etching, cleaning, and stripping equipment designed to achieve industry-leading results. We manufacture a wide range of wet benches, from manual to semi-automated, and fully automated. Our tools feature precise process control, high throughput, and a small footprint. With a focus on proven platforms and custom-designed systems, we redefine innovation in semiconductor wet processing.

RENA Technologies offers batch, single wafer and spray semiconductor etching equipment, tailored to meet the diverse demands. Our surface treatment tools are designed to process a wide range of semiconductor materials, including Silicon (Si), Silicon Carbide (SiC), Gallium Nitride (GaN), Gallium Arsenide (GaAs), and Indium Phosphide (InP).

These solutions are engineered to support the fabrication of integrated circuits (ICs), MEMS sensors, photonic devices, RF components, and power electronics. We also provide electroplating platforms with robust capabilities for plating pure metals like gold (Au), silver (Ag), copper (Cu), and nickel (Ni), along with an array of metal alloys.

We continue to innovate with solutions for wafer sizes ranging from 150 mm, 200 mm and up to 300 mm (6" and 8" and up to 12"). With over 30 years of experience, our established platforms for front-end-of-line (FEOL) and back-end-of-line (BEOL), along with our customized solutions, ensure that RENA machines continue to be a long-term success story.