VaporDry – IPA dryer for semiconductor applications

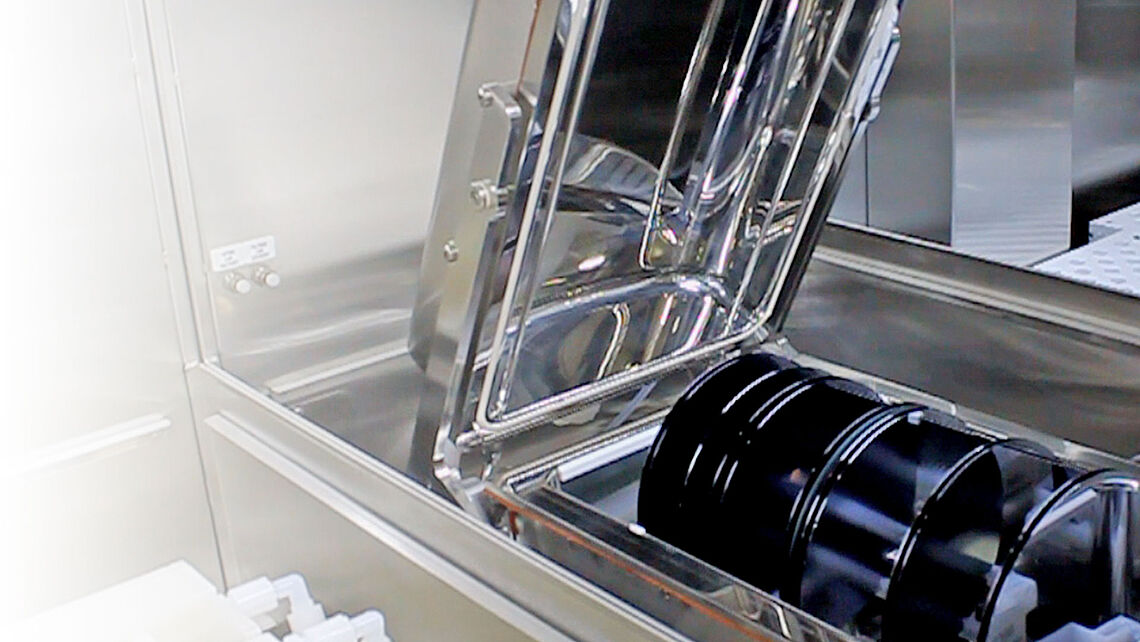

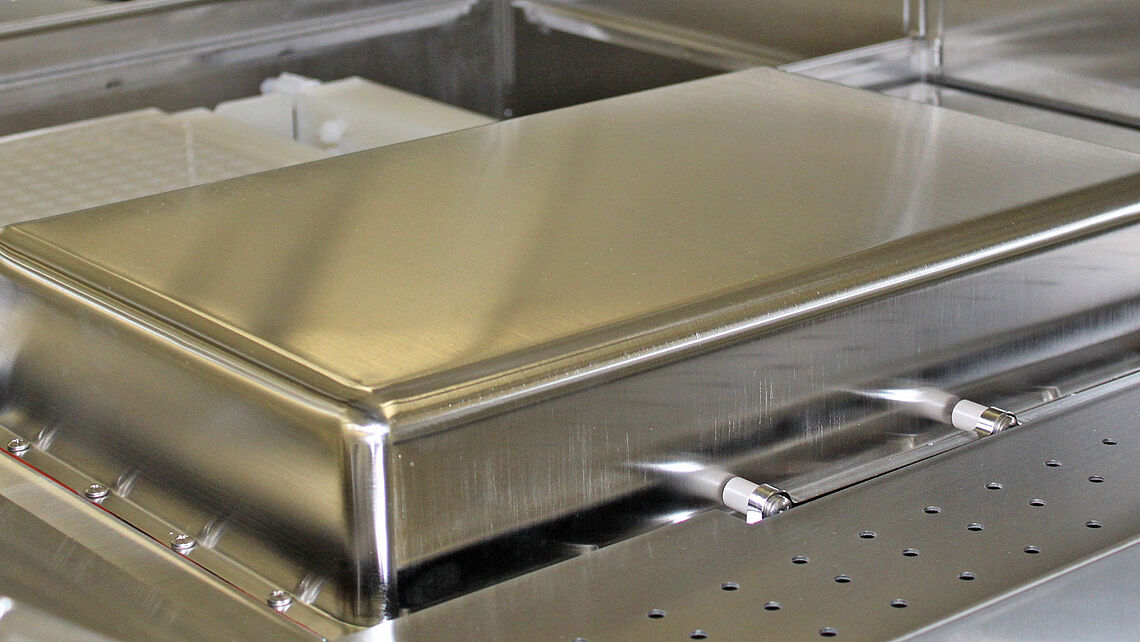

RENA VaporDryer integrates IPA drying process with cleaning and rinsing to provide a single-step process. It is an ideal solution for displacing water from high aspect ratio features and through silicon vias (TSVs) as well as for effective drying of complex surfaces. VaporDry can be integrated into RENA batch immersion platforms. This dryer can be applied for both FEoL and BEoL applications. The entire process is monitored and controlled by RENA’s advanced IDX Flexware process control software.