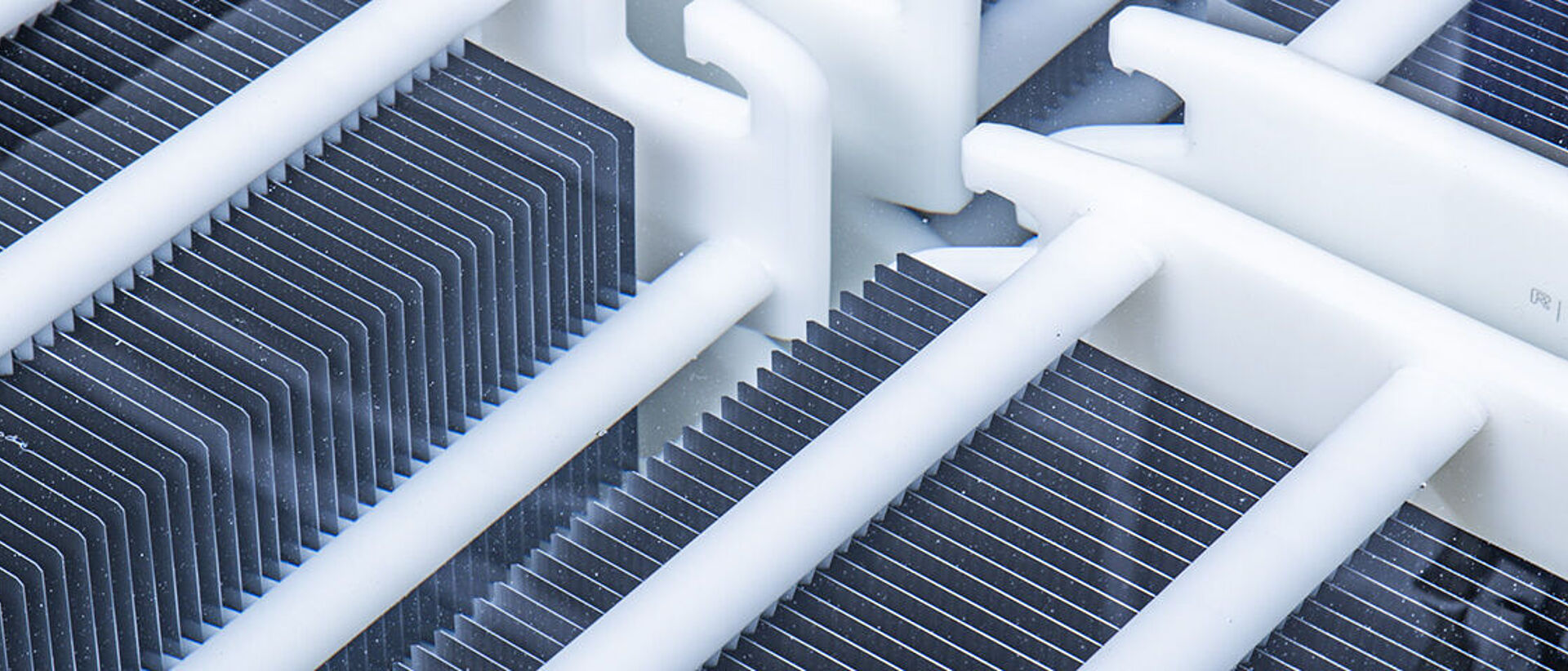

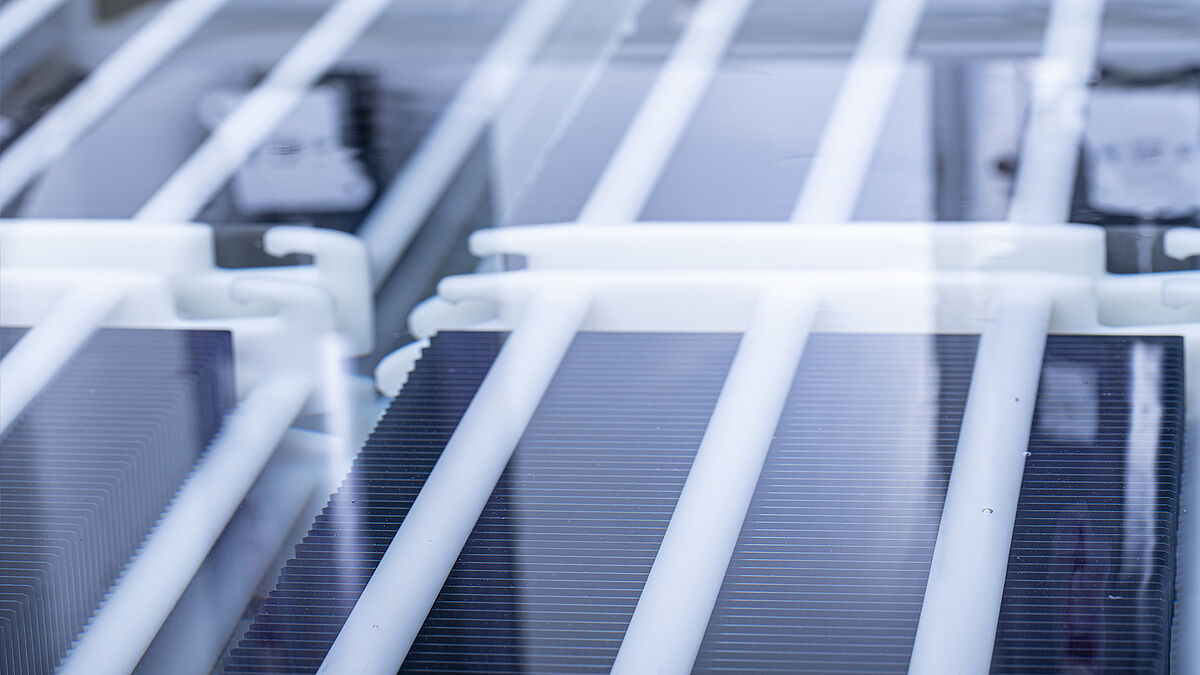

Texturing

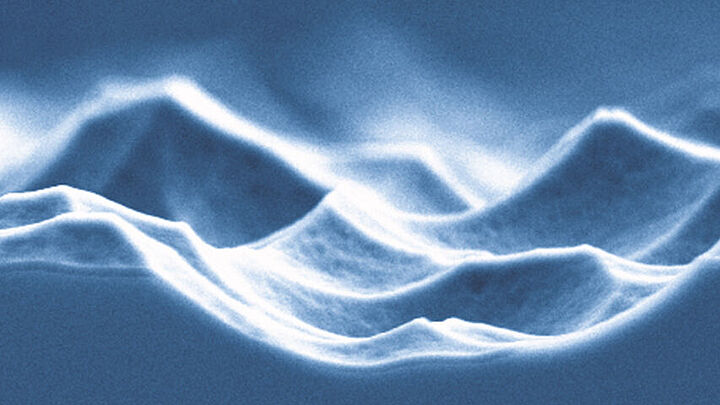

Alkaline texturing is still the state of the art for silicon-based solar cell technology leading to high efficiency of solar cells. The sawed silicon wafers will be cleaned and afterwards the alkaline texturing process takes place. The texturing process will etch surface of silicon, that we obtain a surface with pyramids. This will reduce the reflection of the light to maximize the light absorption into the silicon material, leading to a higher efficiency of the solar cells.

Without any additive the surface of the silicon wafer will be etched in the alkaline process only planar, while additives influence the etching direction. With texturing additives like monoTEX® the anisotropic etching is preferred and we obtain a etched surface with homogenously distributed pyramids and a low reflection.