Single Side Oxide Etching

High throughput next generation rear side etching

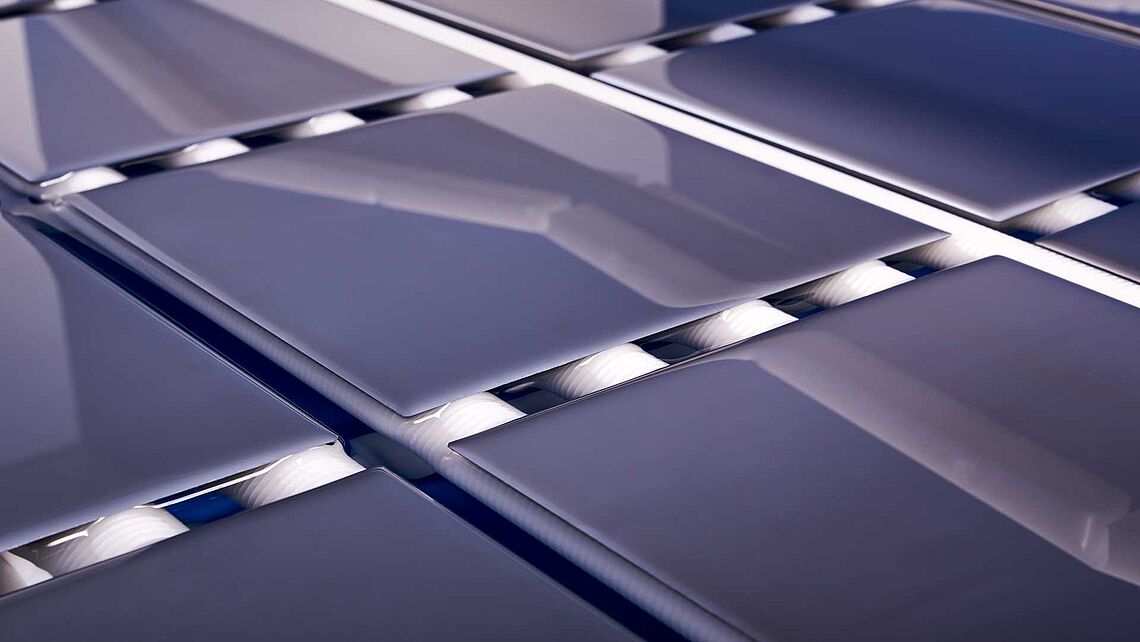

The RENA InEtchSide automated processing equipment is designed for ultra-high throughput removal of silicon oxide layers and doped glasses (e.g. PSG or BSG). The proven and optimized, patented single side etching process ensures lowest chemical front side attack. This is used in the fabrication of high efficiency solar cell concepts, like IBC, PERC, TOPCon and others. The tool is based upon the RENA NIAK 4 inline platform.