MEMS & Sensors

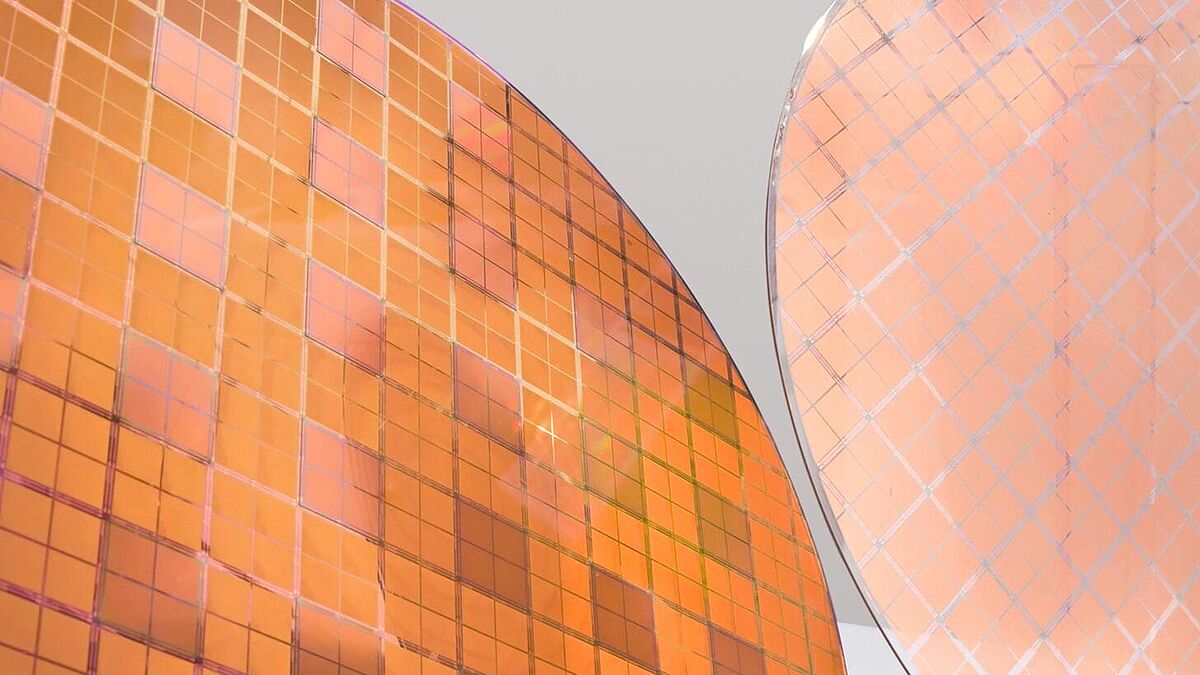

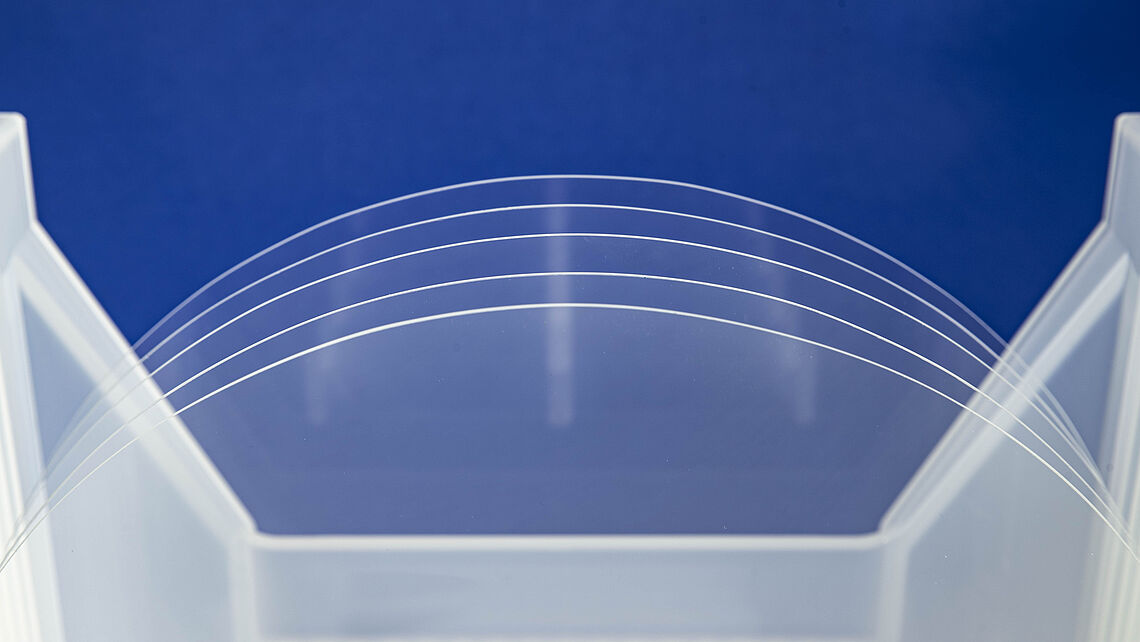

The technology for the microfabrication of glass is gaining in importance because more and more glass substrates are currently being used to fabricate MEMS devices. Today, the glass material is strongly integrated into MEMS pressure sensors and optical MEMS as well as MEMS acceleration sensors and gyroscopes. Patterned wafers with cavities which can be obtained through etching are used to encapsulate the pressure sensor die. The encapsulation is done by using a wafer level packaging (WLP) approach.