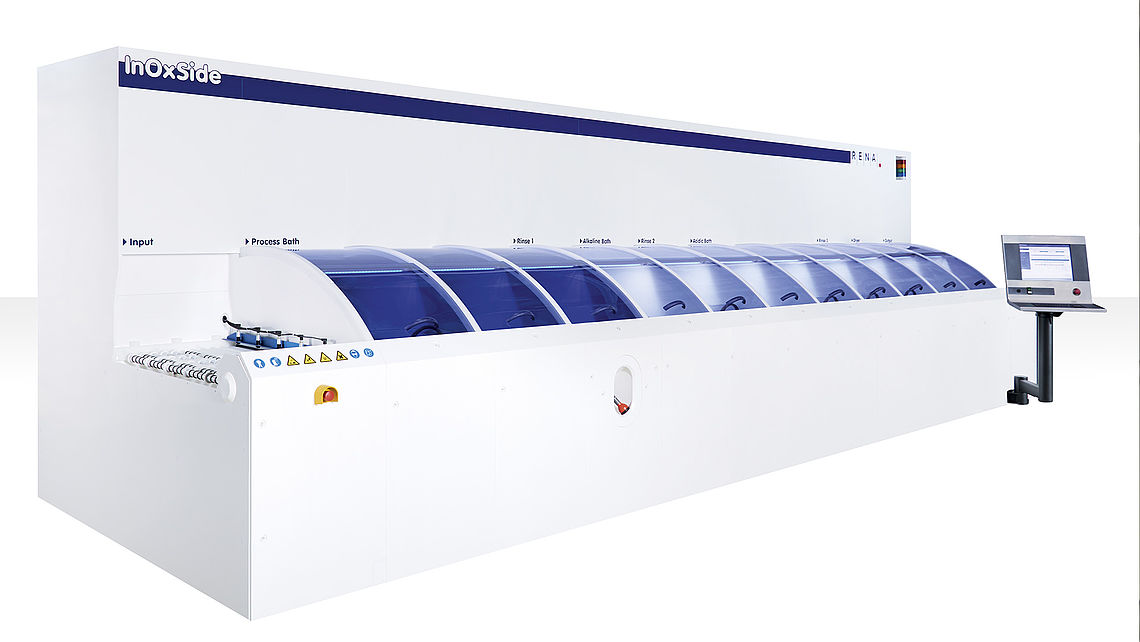

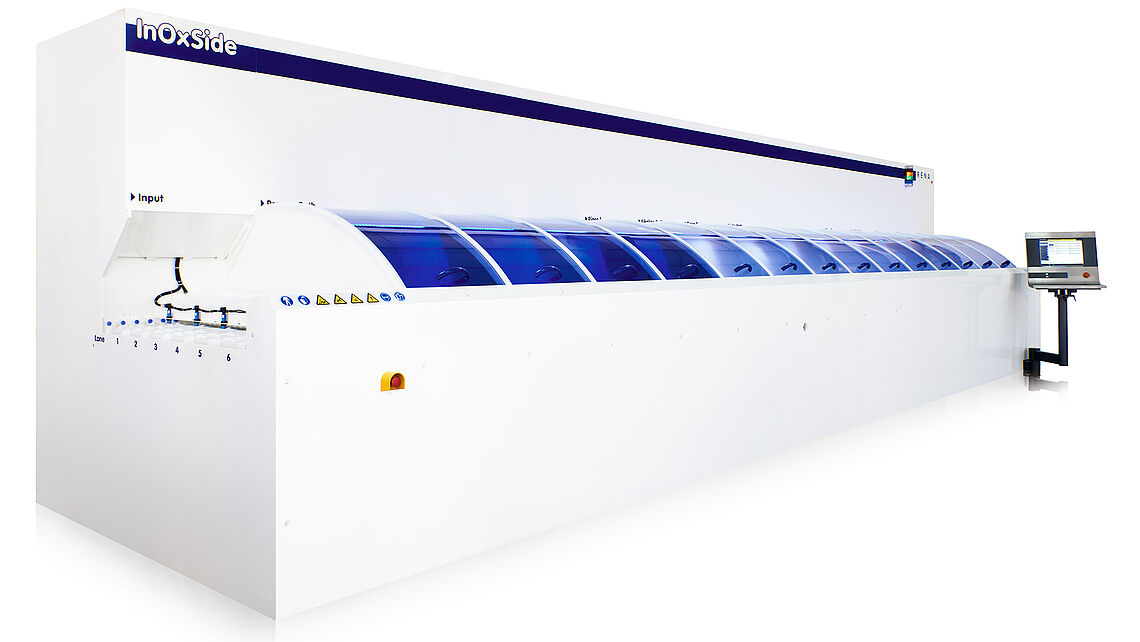

Best-in-class solution for edge isolation, polishing and glass removal

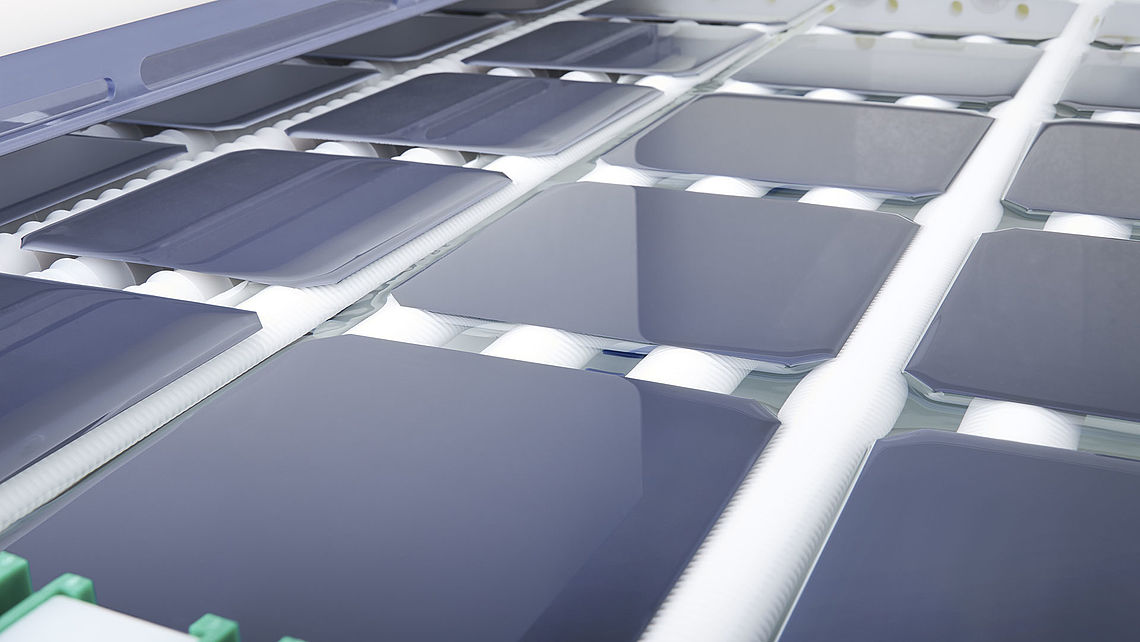

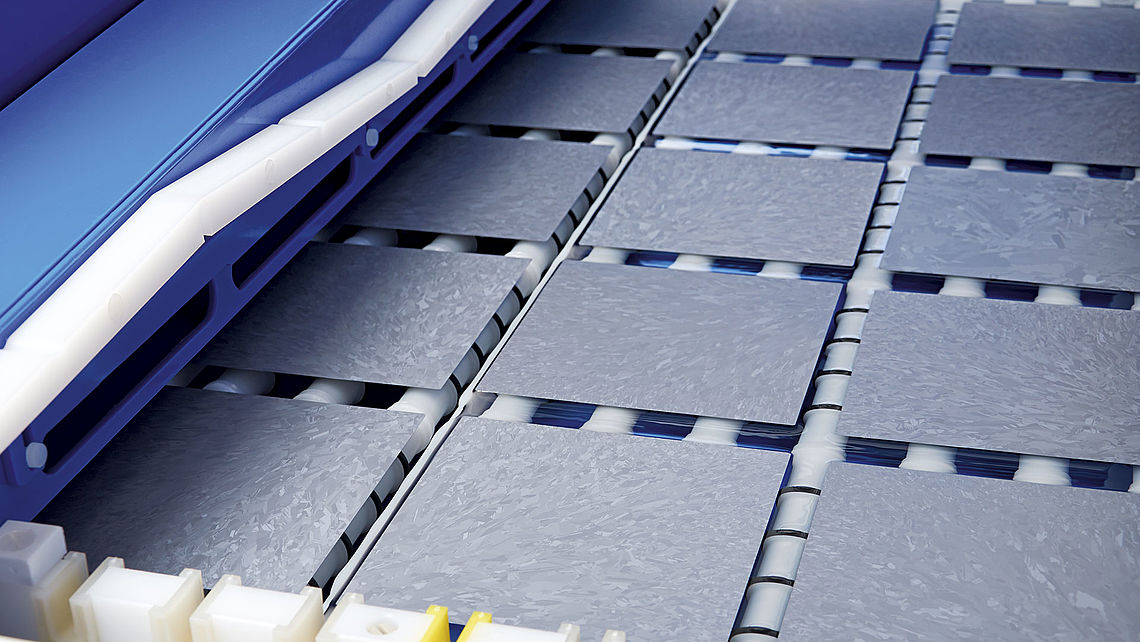

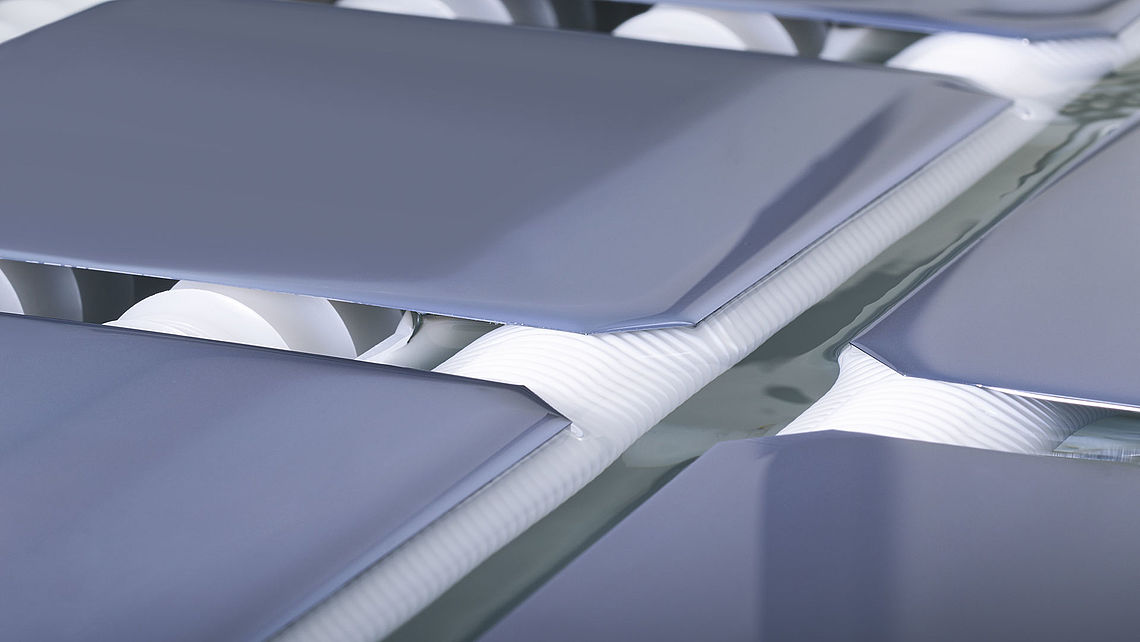

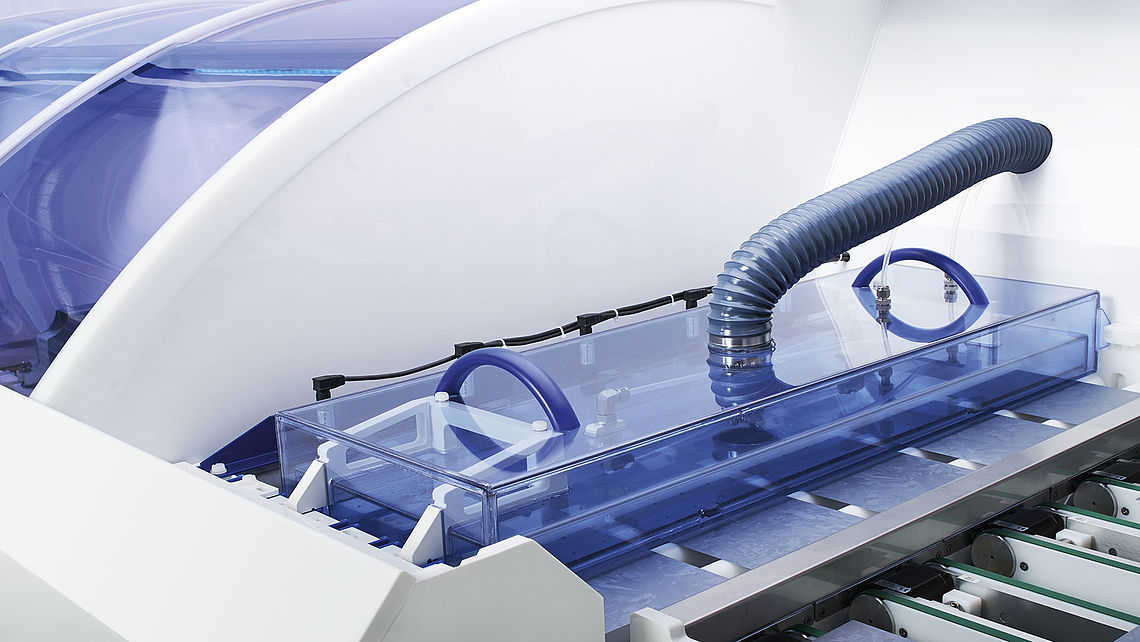

The RENA InOxSide® 3 automated processing equipment is designed as an integrated solution for edge isolation, rear side polishing and doped glass removal of silicon solar cells. Using the process for lowest cost of ownership and best performance, the InOxSide® technology is the best choice for fabrication of Al-BSF, PERC and PERT silicon solar cells. It is based upon the RENA NIAK inline platform.