What is DI water?

DI water means deionized water. The salts, ions or minerals found in normal spring and tap water are not present in deionized water. DI water has a particularly low conductivity.

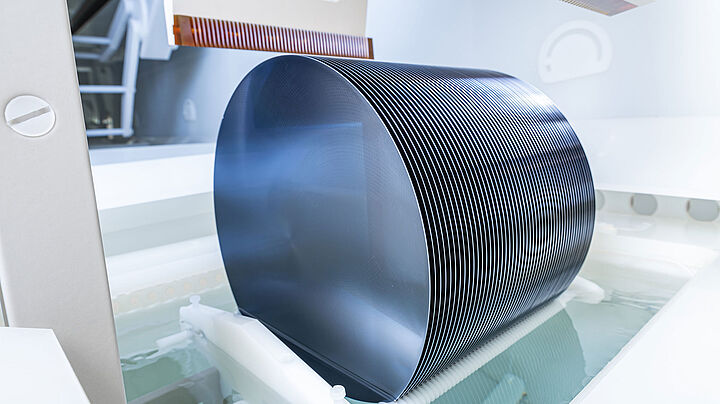

At RENA Technologies, it is used in the drying process of wafers (e.g. silicon carbide/SiC wafers, glass wafers) in the wafer production process.

How is DI water made?

DI water is obtained from drinking water through reverse osmosis, electrodeionization, membrane degassing or the use of ion exchangers. This completely removes the salts present in the source water or replaces them with ions of the same type. For example, the calcium ions dissolved in tap water are replaced by sodium ions.

Where is DI water used?

DI water is used in medicine, biology and chemistry to clean equipment and containers. It leaves no limescale residue and is ideal for cleaning surfaces and materials in cleanrooms. However, it must be borne in mind that pure water has a limited shelf life.

What is DI water used for at RENA?

It is used to dry wafers in the production of semiconductors, microchips and solar cells. Spin drying is one of the common methods for drying wafers (e.g. silicon carbide/SiC wafers, glass wafers) in semiconductor production. After the wafers have been rinsed with high-purity deionized water (DI) under nitrogen (N2), this method involves rapid mechanical rotation around an axis perpendicular to the surface of the wafers. Hot water dryers are also widely used in semiconductor and solar cell production.

Welche Trocknungsplattformen werden bei RENA Technologies eingesetzt?

RENA Technologies liefert unter anderem an Unternehmen im Bereich der Microchip Fertigung und Solarzellen Fertigung. Die Produktionsanlagen zur nasschemischen Oberflächenbehandlung von Wafern bei RENA bieten verschiedene Arten von integrierten und eigenständigen Wafer-Trocknungsplattformen zur Wafer Trocknung an:

SRD Trocknung, VaporDry sowie der Genesis Marangoni Dryer, der von RENA patentierte Trockner, der auf dem Marangoni-Effekt basiert.