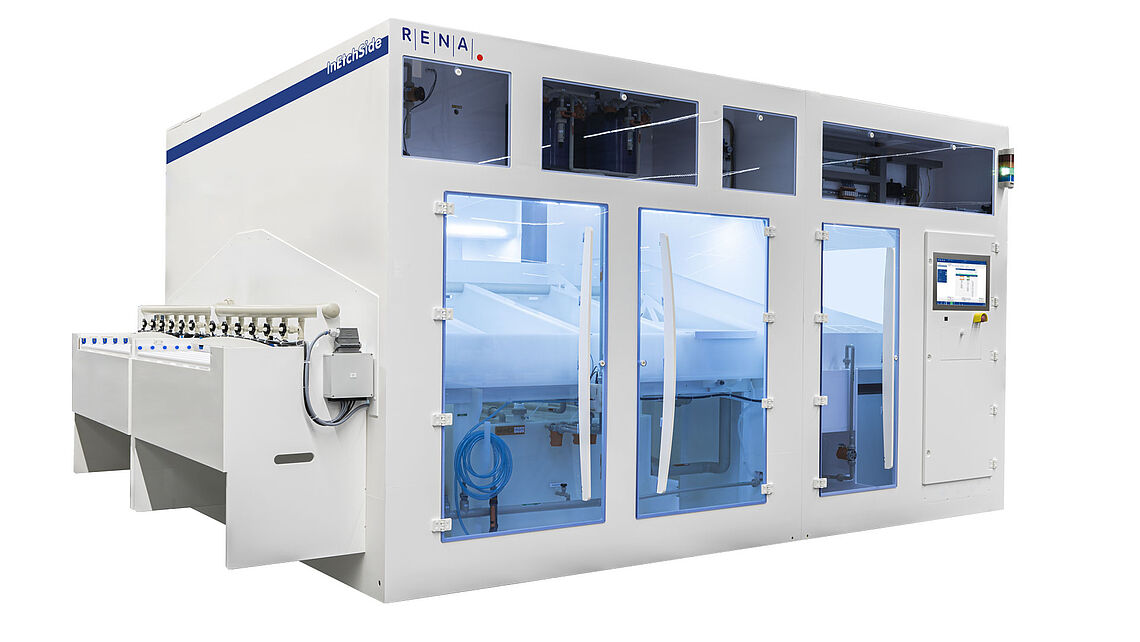

High Throughput Single Side Oxide Etching

Improved Throughput Next Generation Rear Side Etching

The RENA InEtchSide 4+ automated processing equipment is designed for removal of silicon oxide layers and doped glasses (e.g. PSG or BSG). The ultra-high throughput on up to 14 lanes provide highest yield and mark a significant improvement to it`s predecessor. The proven and optimized, patented single side etching process (RFL - Water Capping) ensures lowest chemical front side attack. The tool used in IBC, TOPCon or other high efficiency solar cell concept manufacturing. Ideally combined with the RENA BatchEtch and RENA BatchPolyClean series the cluster handles all known wafer formats.