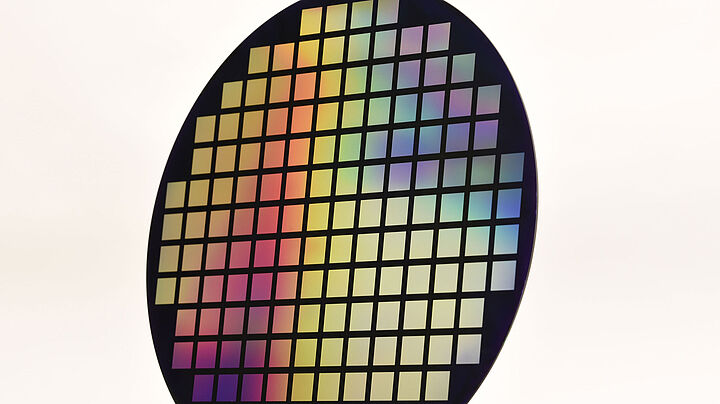

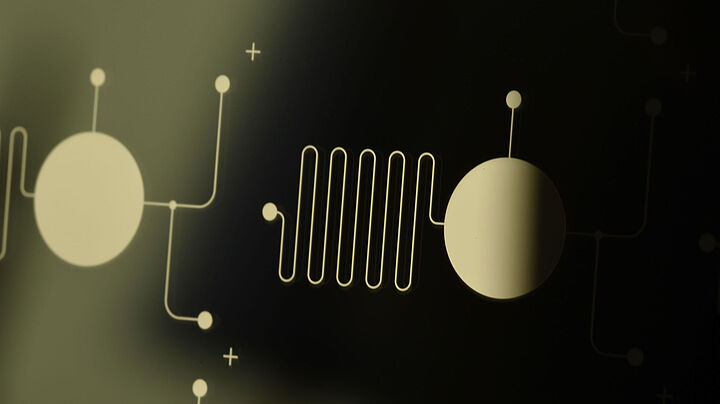

Glass Wafer Processing

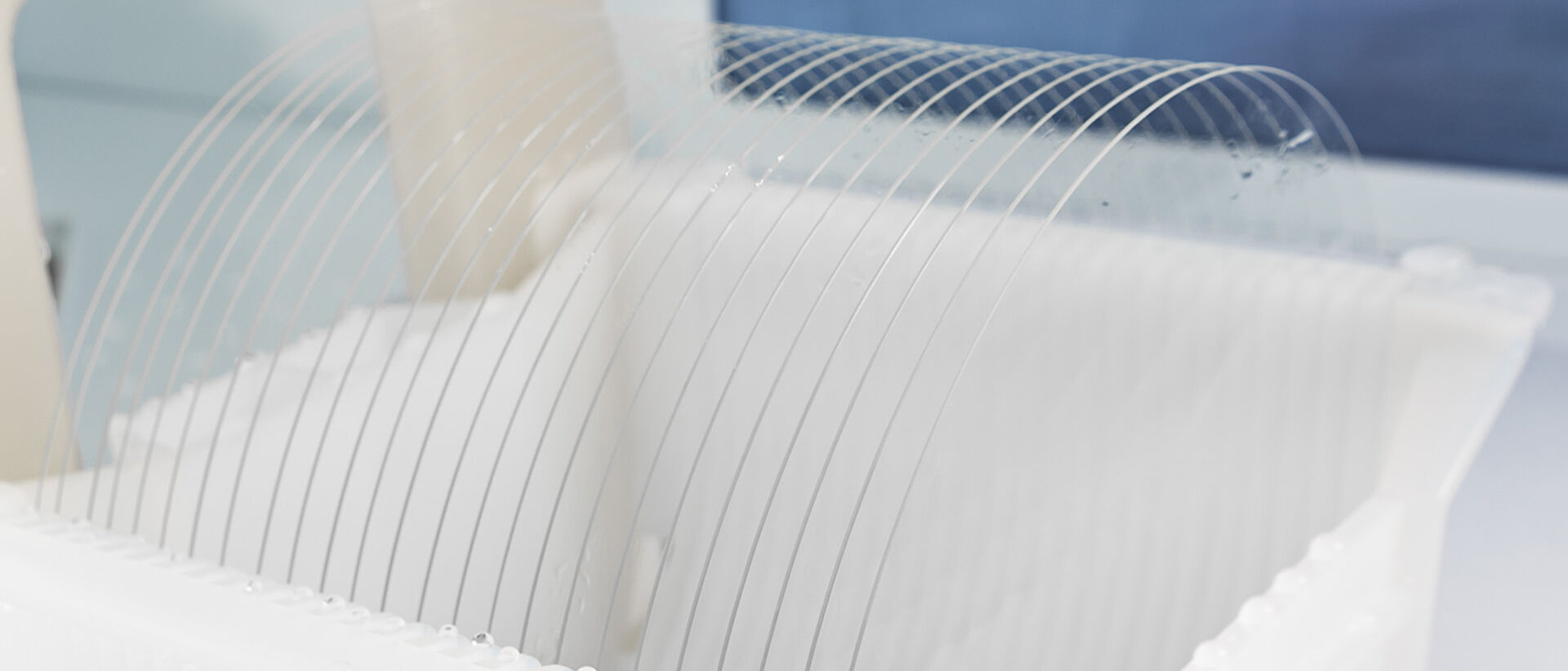

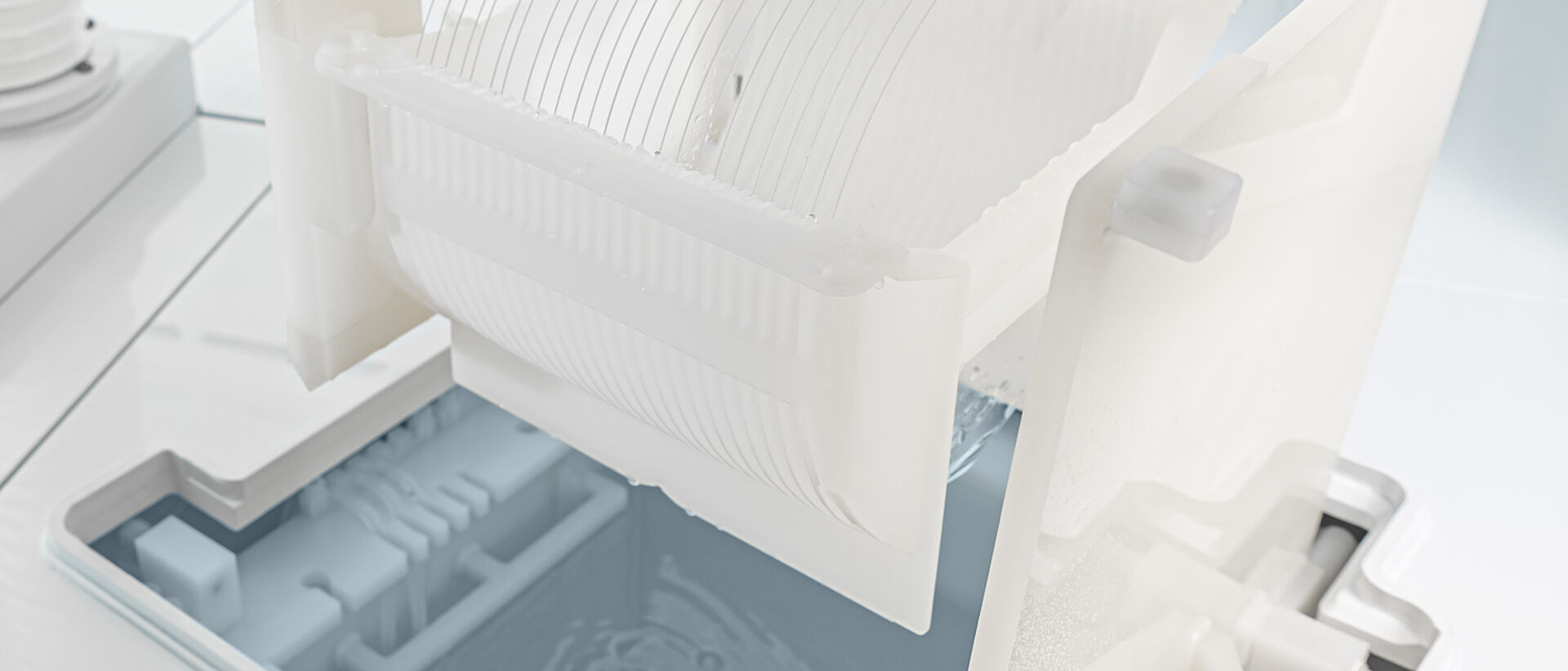

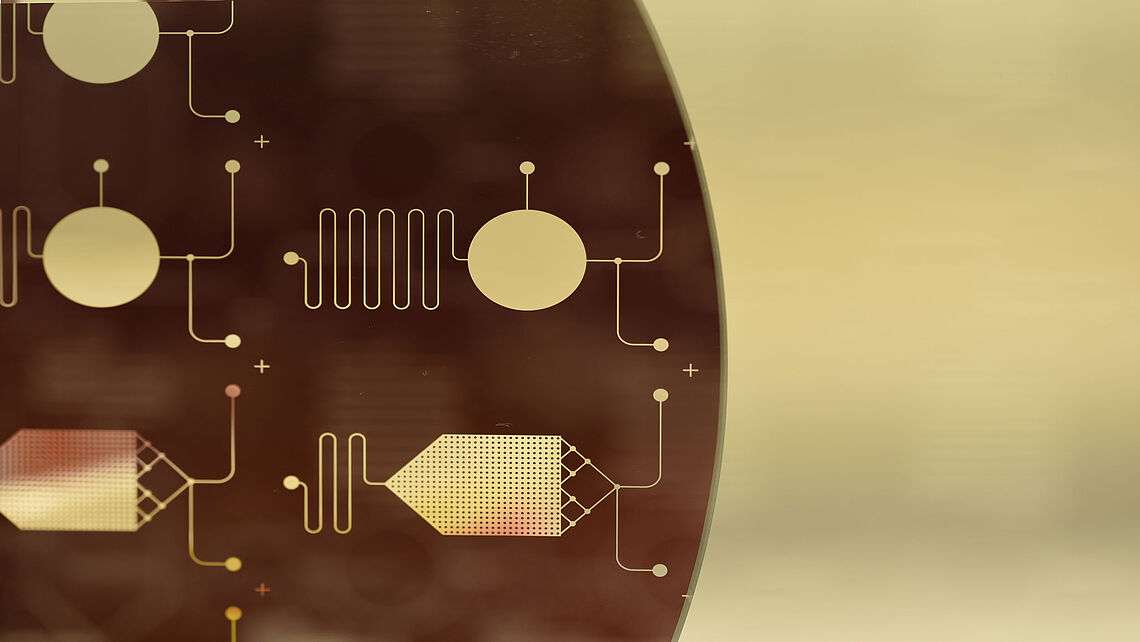

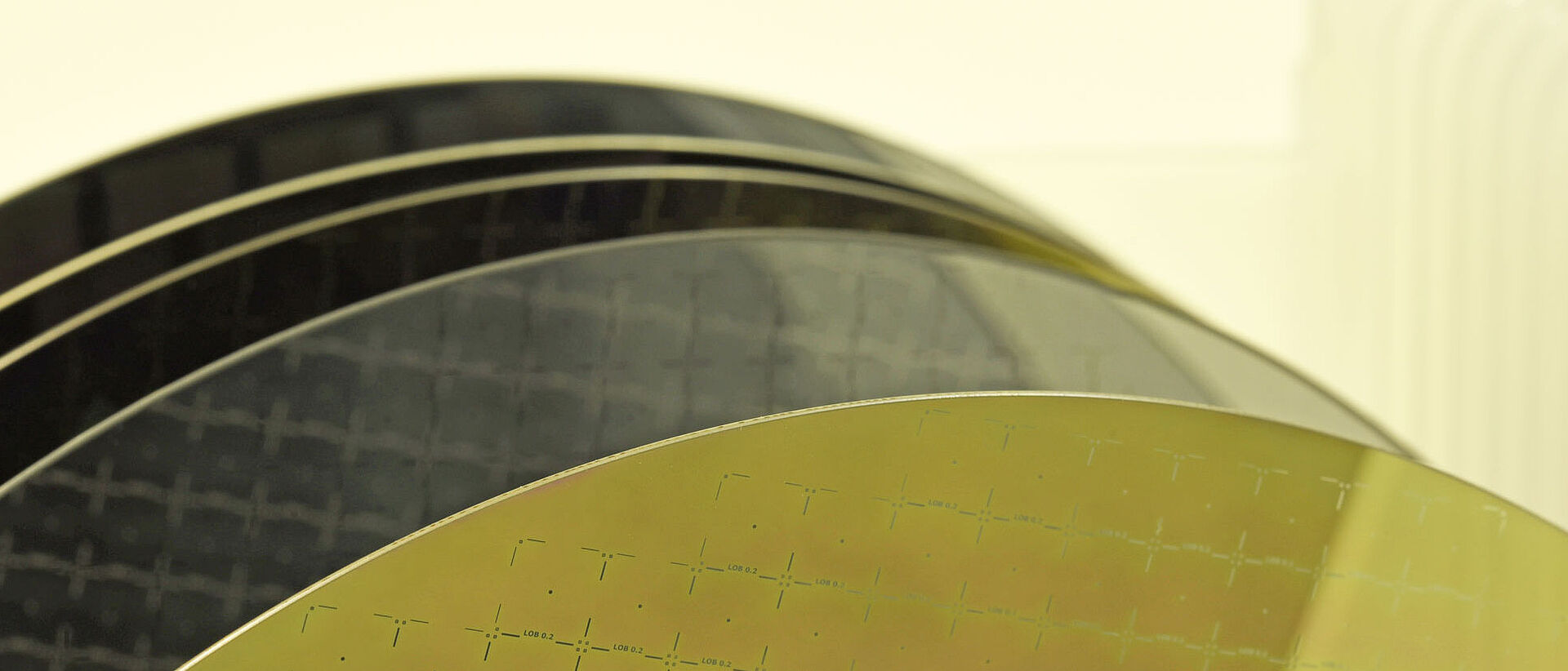

Wafers, made of glass, are the basis of the modern micro system technology. Glass has many advantages as a material such as high chemical and heat resistance, high electrical isolation, biocompatibility, large optical transition range as well as low optical absorption. Due to these properties, glass wafers are widely used in conventional microfabrication processes. RENA offers small scale tools for wet processing of glass wafers.